Manufactured from high-impact, UV stabilised SMP polymer, Aegis Cases provide unmatched protection performance. The rotational moulding process produces a consistent wall thickness that can be changed according to customer requirements without the need for new tooling.

Aegis Cases are engineered with a double-skin lid, optional double-skin body available, for maximum rigidity and impact resistance, all rims are double walled for extra strength and to accommodate the custom designed waterproof seal.

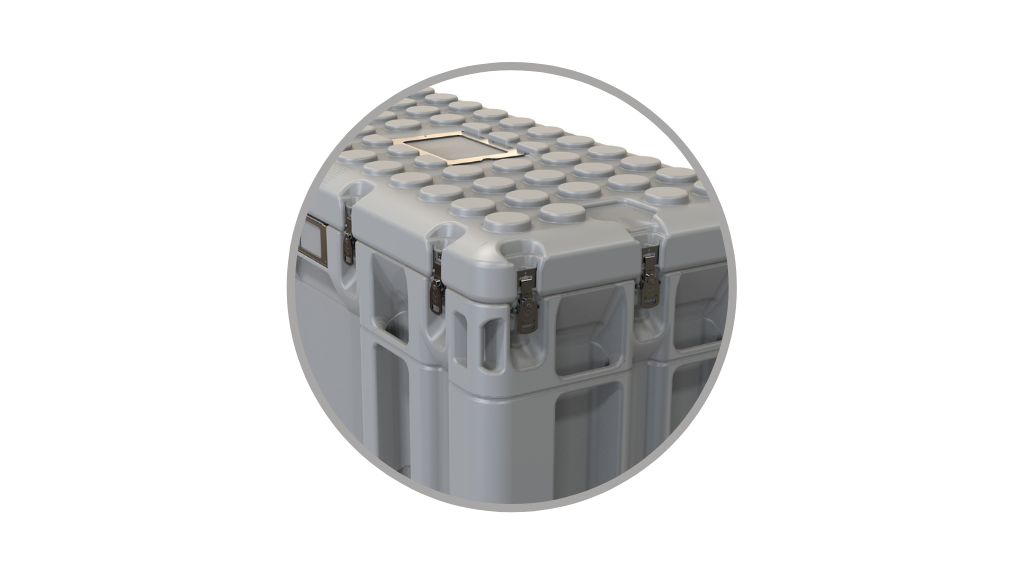

Unique stacking feature that enables them to be stacked securely and even cross- stacked in either orientation, with optimum stability. The stacking feature is compatible across all cases, even non-matched sizes, and virtually eliminates load movement during transit.

The stacking feature also enhances case stiffness and structural integrity. The clever geometry of this stacking feature overcomes the water retention problems often found in cases with cube stacking features.

Integral tie-down anchor points offer an ideal way of securing loads without compromising the sealed integrity of the case. Located at the corners of the case, Aegis tie-down points minimise the potential for load shifting and are easy to access and use, even when wearing gloves.

Subject to the case specification these tie-down points may be located near the top, base or side of the Aegis Case. The integral handles can also be utilised as tie-down points if preferred.

Unlike the majority of transit cases, Aegis Cases offer integral flush handles for extreme strength and reliability in all weathers, the ergonomic grip handles have no moving parts making them weatherproof, glove friendly and non-trapping.

Being designed within the overall dimension of the case, the handles are completely non-protruding making them safe to use and snag free during transit and handling. They are also ideal to use as tie down features during transit and cannot be pulled from the case.

Latches attach to moulded-in metal inserts that distribute the load for long-term serviceability without piercing the case envelope and are manufactured from 316 marine grade stainless and will not rust, even under the harshest of environmental conditions.

The stainless steel catch plates are unique in that they are ‘driven in’ during the manufacturing process, removing the need for riveting, which could compromise the integrity of the case. Each latch wing can be padlocked to its respective drive in catch plate for ultimate security or connected with a plastic tie as a tamper deterrent.

To ensure no leakage on the hingeside of the lid of our cases, our design and engineering team developed a compression latch that guarantees satisfactory waterproofing to IP67 standards.

Much like with our stainless steel catch plates are unique in that they are ‘driven in’ during the manufacturing process, removing the need for riveting, which could compromise the integrity of the case. Each latch wing can be padlocked to its respective drive in catch plate for ultimate security or connected with a plastic tie as a tamper deterrent.

The waterproofing seal used in all Aegis watertight cases is custom designed for a precise and effective fit. It will resist deformation and fatigue, ensuring a long lasting watertight seal.

Our Aegis IP67 rated waterproof cases are ideal for applications such as military, in all theatres of operation, search and rescue, marine transportation, etc.

For the production of functional prototypes and to meet low volume requirements for bespoke cases, Leafield has developed Advanced Cut and Weld technology.

Cases can be modified in all three dimensions without detriment to their strength or structural integrity. The performance features, including waterproof & dust proof characteristics and stacking, are maintained due to the high reliability of the Advanced Cut and Weld process.

Curved lid surface for water drainage.

Enhanced double skin lid for ultimate rigidity and durability.

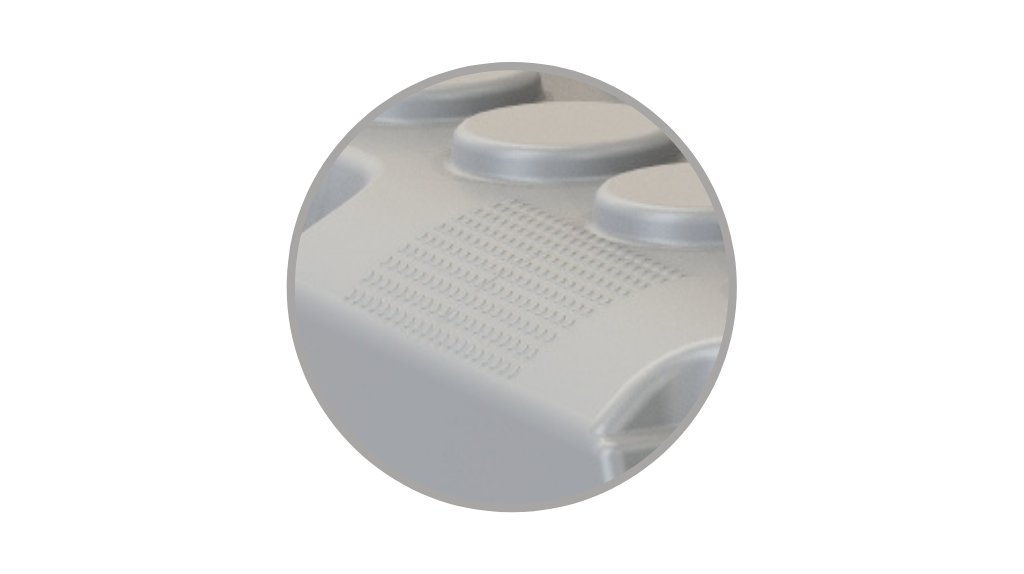

The dimple area for temporary labelling is located on the lid of the case and is available on a selection of the Aegis Cases range.

Please contact us for confirmation of whether this feature is available on the case size of your interest.

Aegis Cases are engineered to comply with applicable US, UK and European military requirements.

Designed and manufactured to meet the requirements of MIL-STD-810G, Def Stan 81-41 Level J, STANAG 4280 and Def Stan 81-144 and exceed ATA 300, Category 1.

These rotationally moulded cases can be designed specifically to suit your weapons and equipment shipping needs, and may include integrated fittings and fixtures and custom foam inserts.